创新,让制造更强大

为应对不同领域复杂多样的客户需求,我们成立了先进材料产业研究院,致力于前沿技术和先进成果的落地转化。在科技创新驱动战略的引领下,由100余名专家和应用工程师组建的技术研发团队,不断挑战前沿技术,在产品开发、技术装备研发方面掌握了多项核心自主知识产权。

20+

行业标准的起草与制定

40+

全球行业和地区认证

170+

实用和新型专利

50年

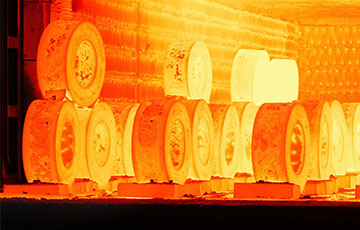

锻造行业经验

40+

世界500强企业认证

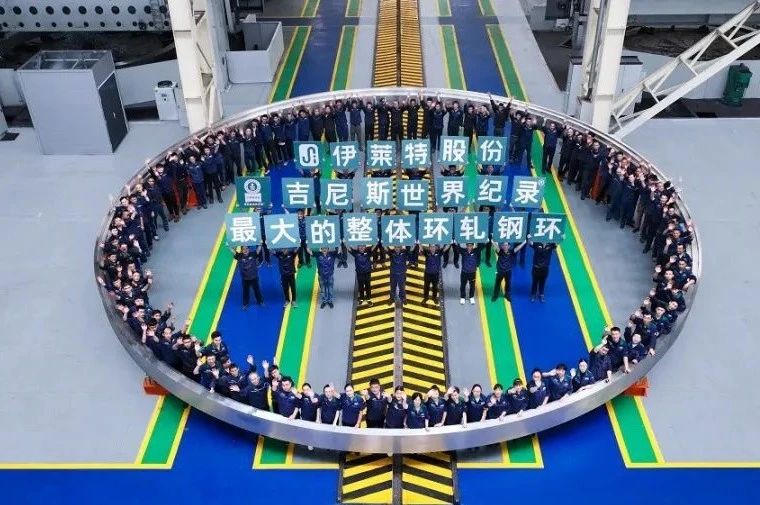

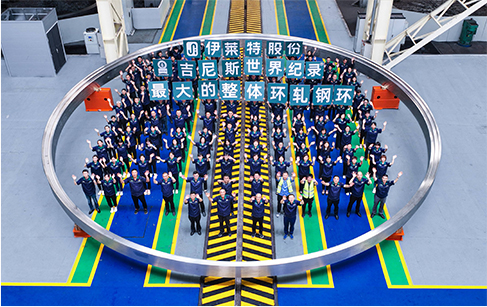

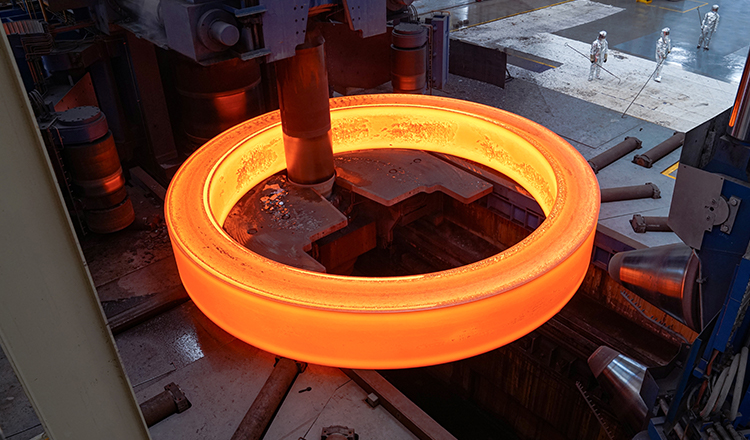

大胆点,释放你的想象力

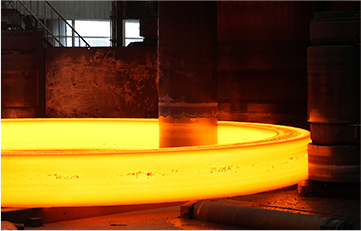

在参与的供应链中,我们致力于长久成为客户不可替代的合作伙伴。为此我们不懈争先,连续为核电、风电、炼化、水泥等多个行业交付创新性材料和部件。当下伊莱特22米超级轧环机项目已经启动,我们负责制造,现在,轮到你尽情释放想象!

探索更多

降低成本

在成本控制这件事上,我们的决心远超你的想象。我们深刻理解成本对于客户业务运营的关键影响,每一项技术创新、每一次流程优化,目的都是为消除一切不必要的繁琐步骤,全力提升生产效率,以更低的成本为客户创造更高的价值。