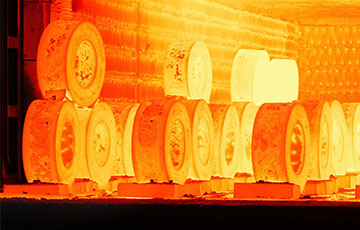

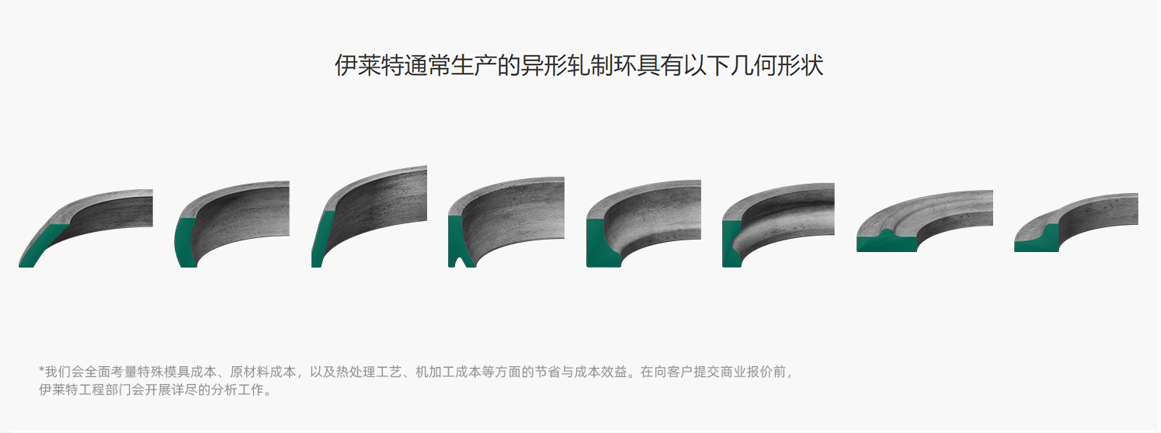

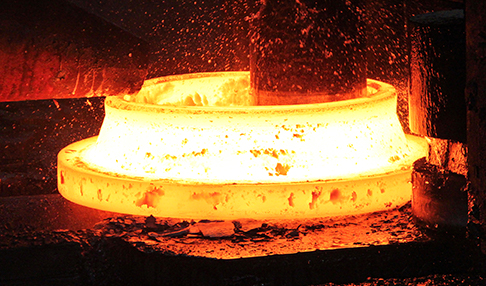

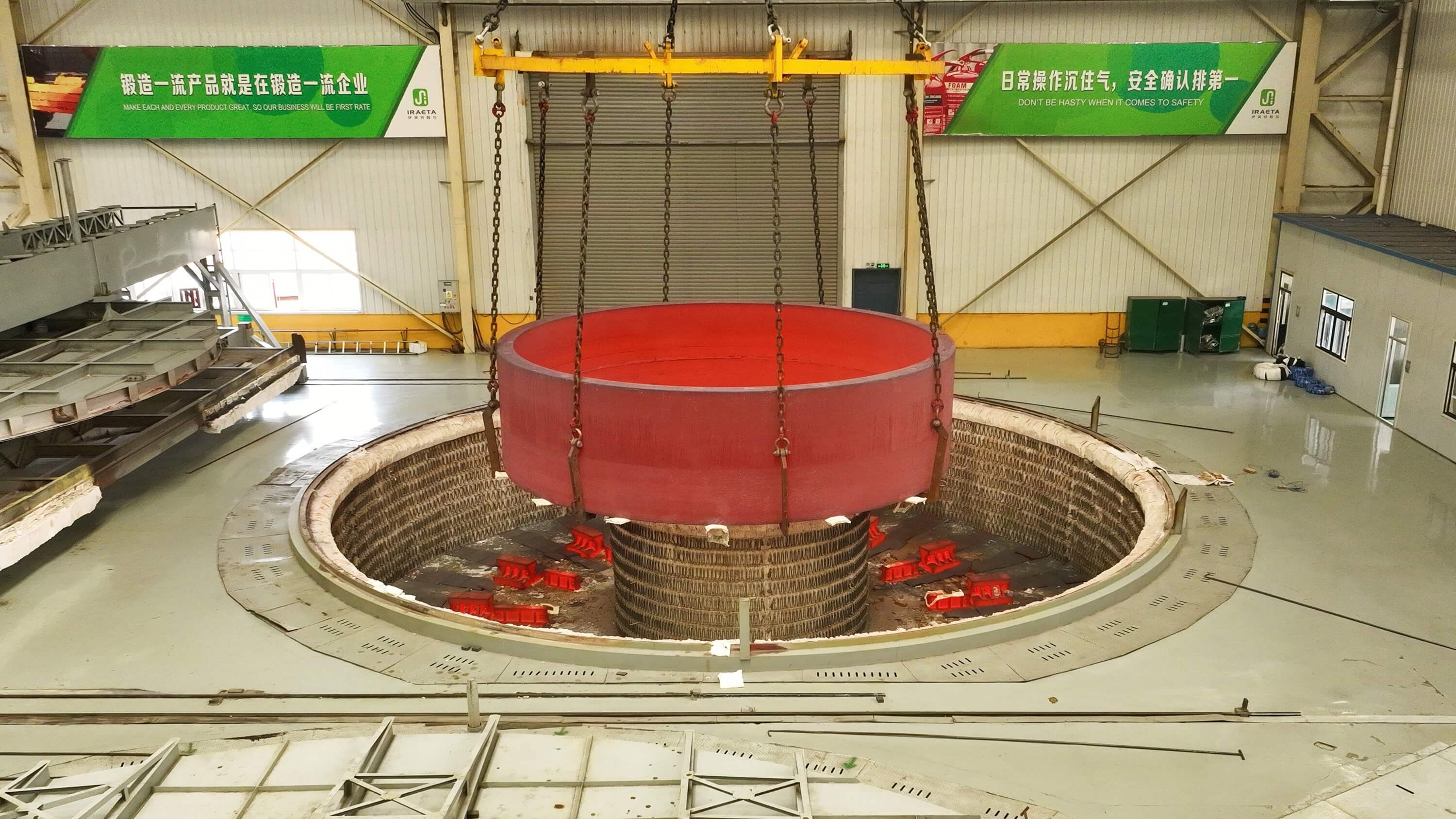

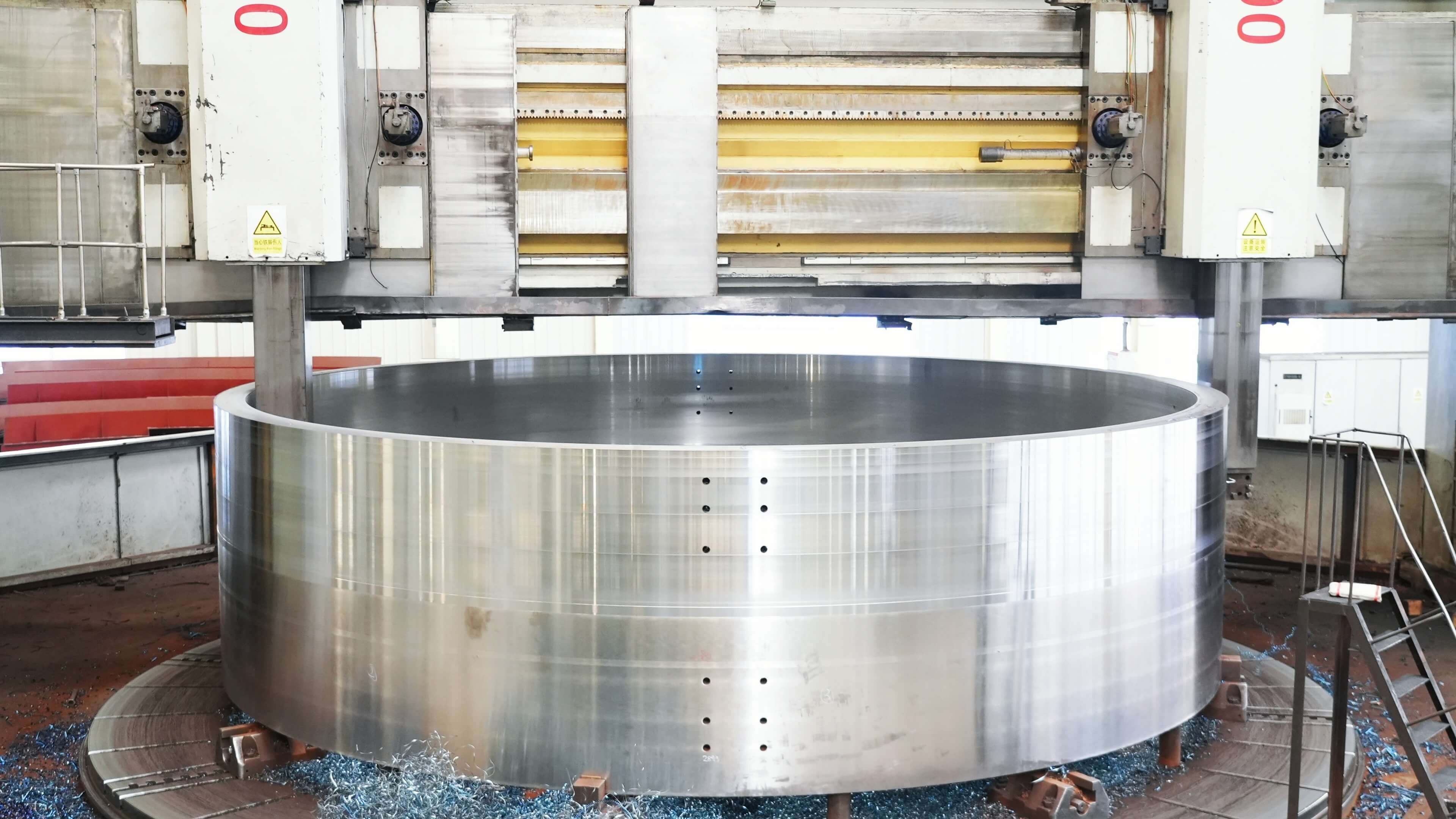

锻造—根据客户规格进行矩形环和异形环轧制

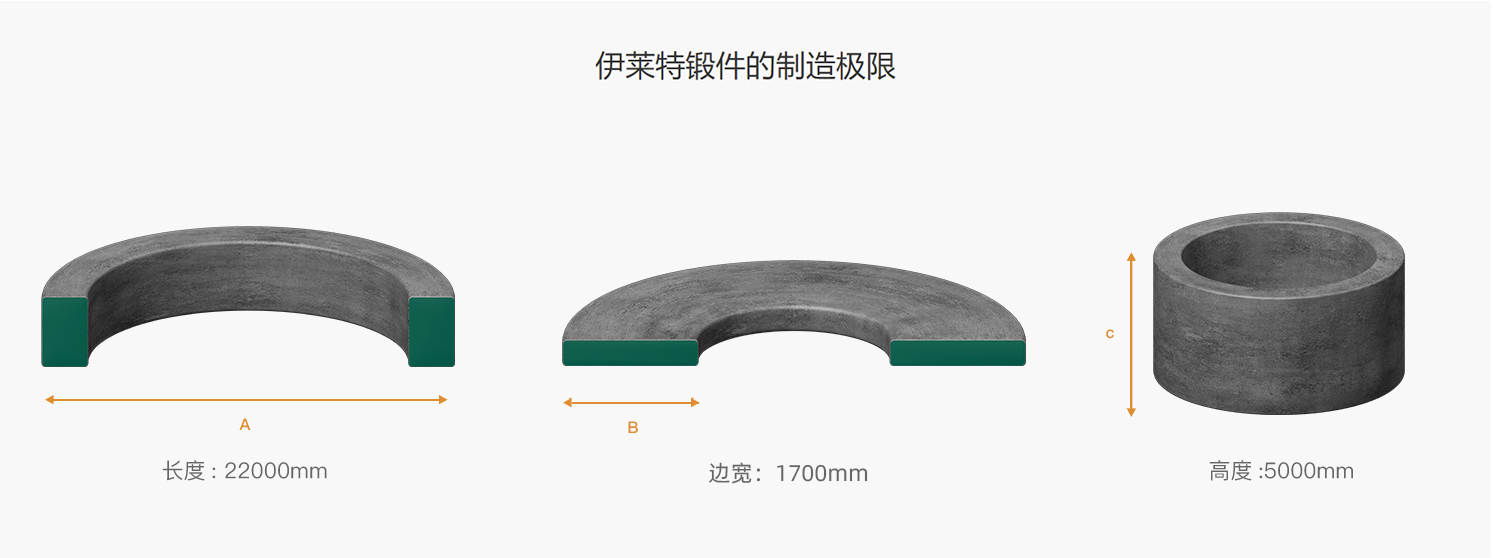

我们配备了2.2万吨自由锻压机和直径22米超级轧环机,强大的设备能力让我们可以轻松应对各类挑战,包括制造矩形截面及特定形状的轧制环。目前,我们可以定制市场上各类环锻件,产品单重可以实现从0.3千克-350吨全覆盖、产品尺寸实现直径从73毫米到22米全覆盖、高度从12.5毫米到5米全覆盖。

展开更多 +

收起 -

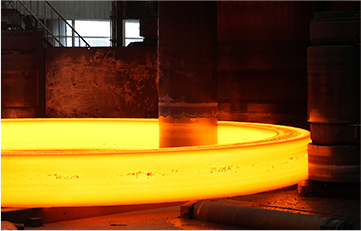

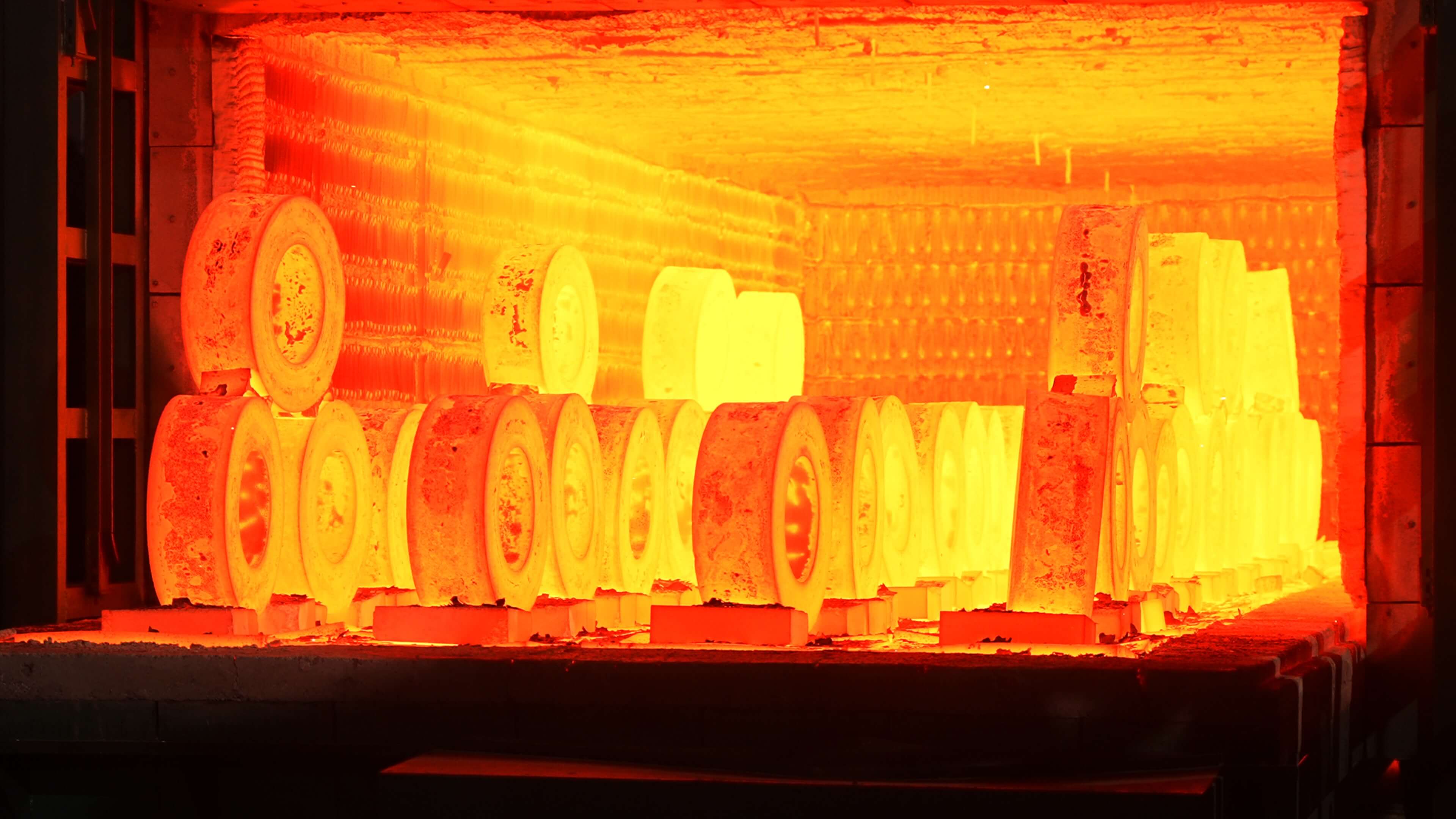

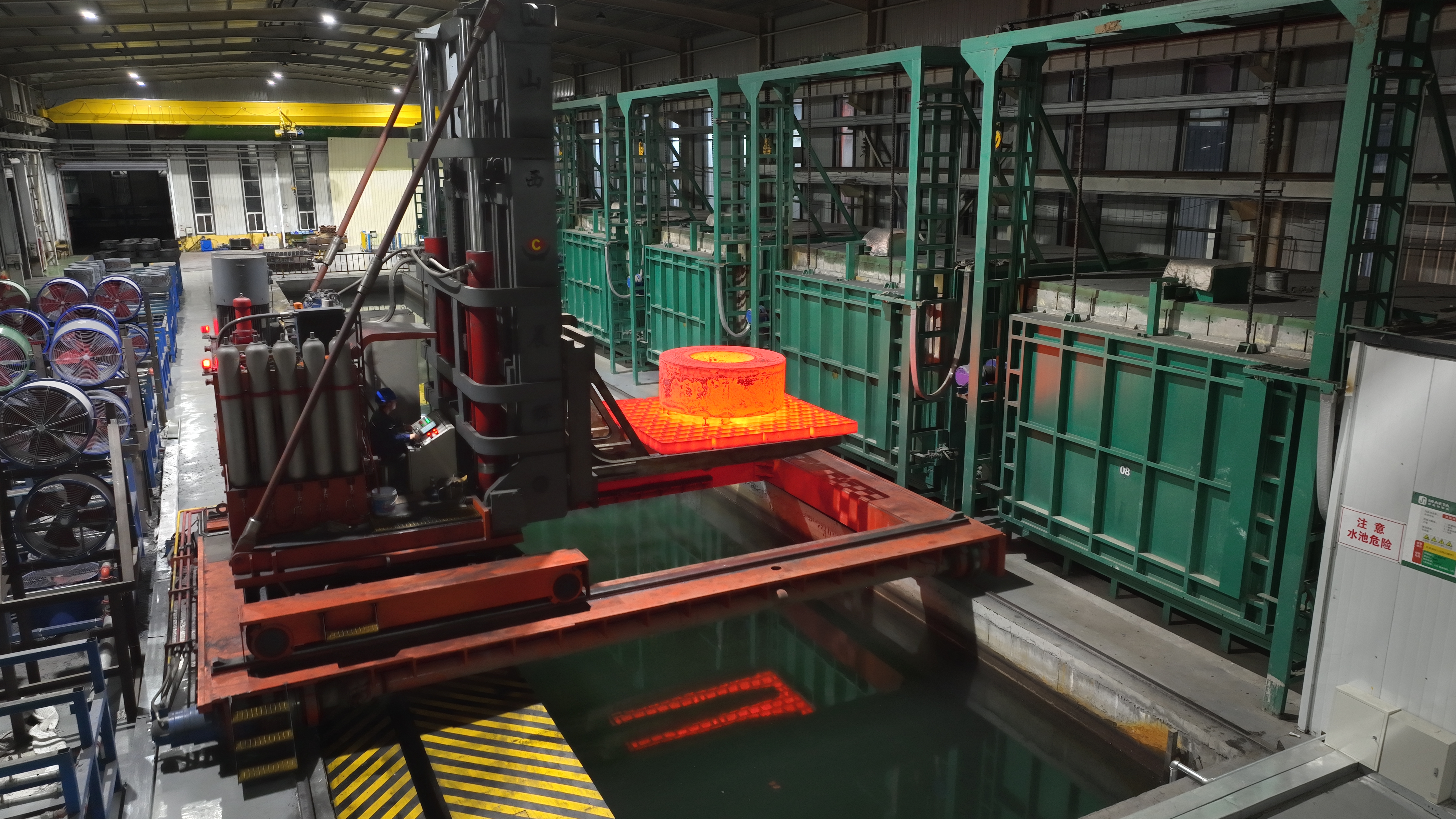

热处理—高标准满足客户所有热处理需求

热处理工艺对于提升金属的强度、硬度、韧性以及耐磨性等机械性能成效显著。伊莱特拥有一支专业且秉持科学态度的热处理技术团队,以一丝不苟的严谨作风合理运用热处理技术,全力打造出品质卓越的金属制品,满足各行业对金属材料的严苛要求。

展开更多 +

收起 -

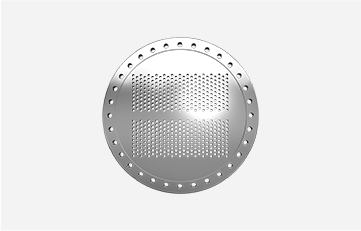

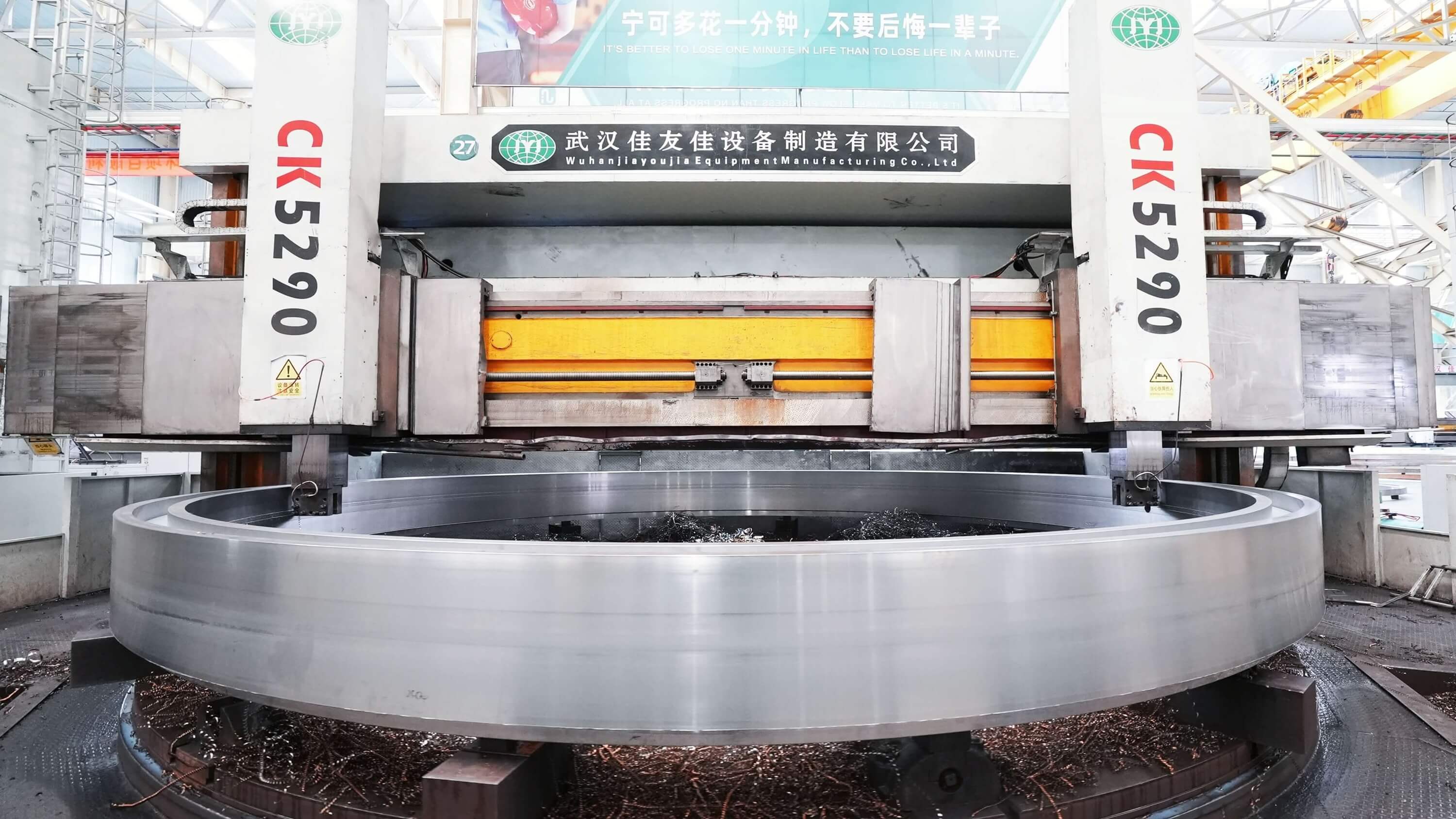

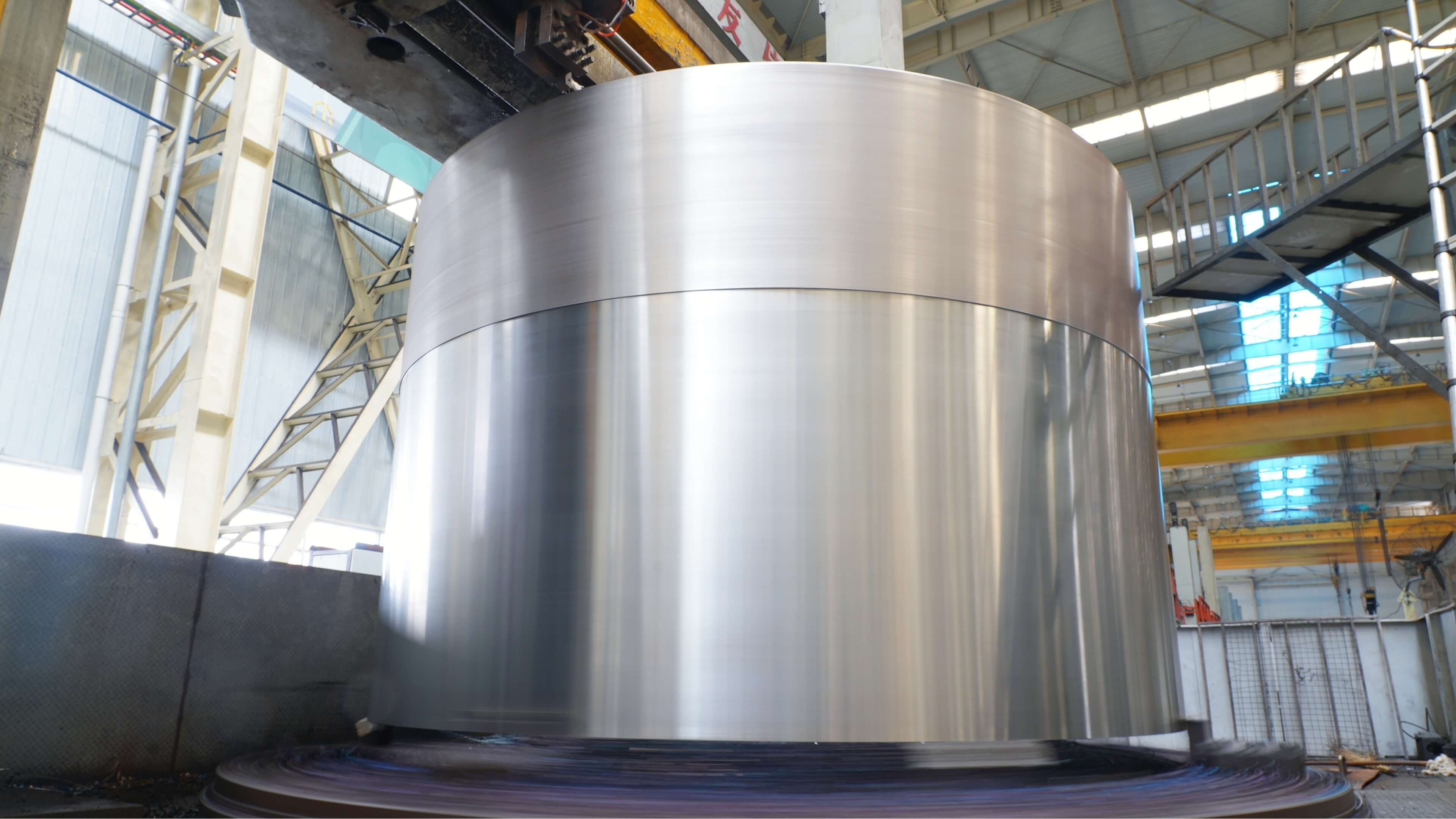

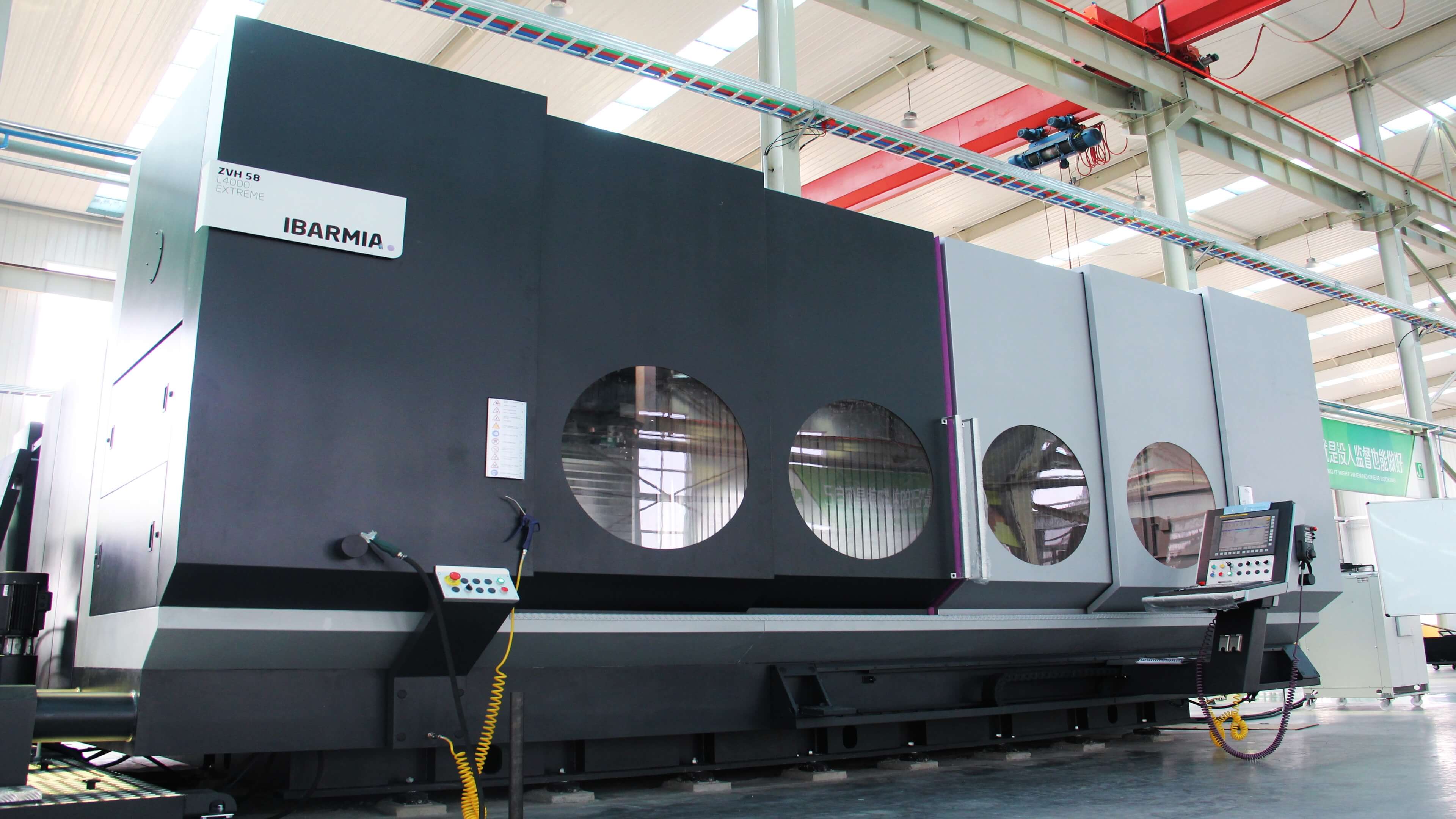

机加工—拥有先进的机加工能力

伊莱特拥有先进的机加工能力。针对不同的金属材料,专业团队凭借精湛技术,结合高端设备,能够精确进行切削、磨削、钻孔等操作,通过数控技术实现复杂形状的加工,确保产品符合设计要求。

展开更多 +

收起 -