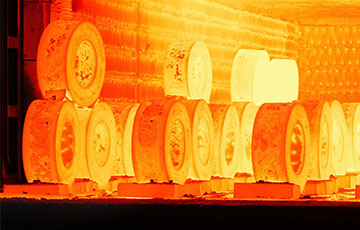

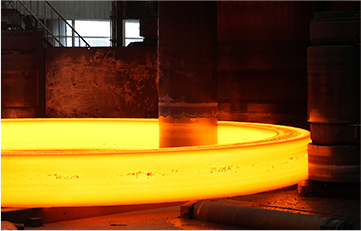

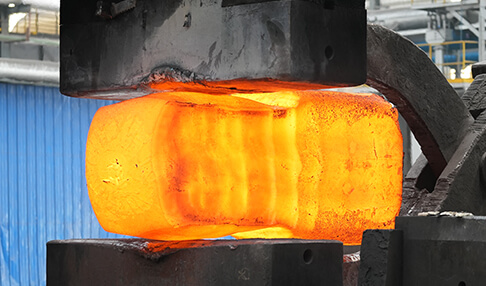

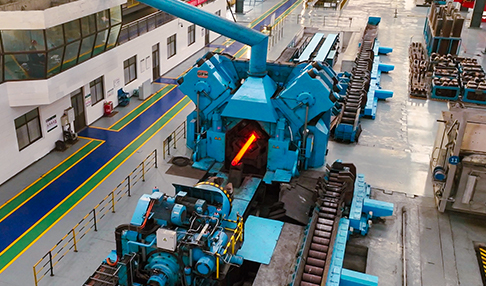

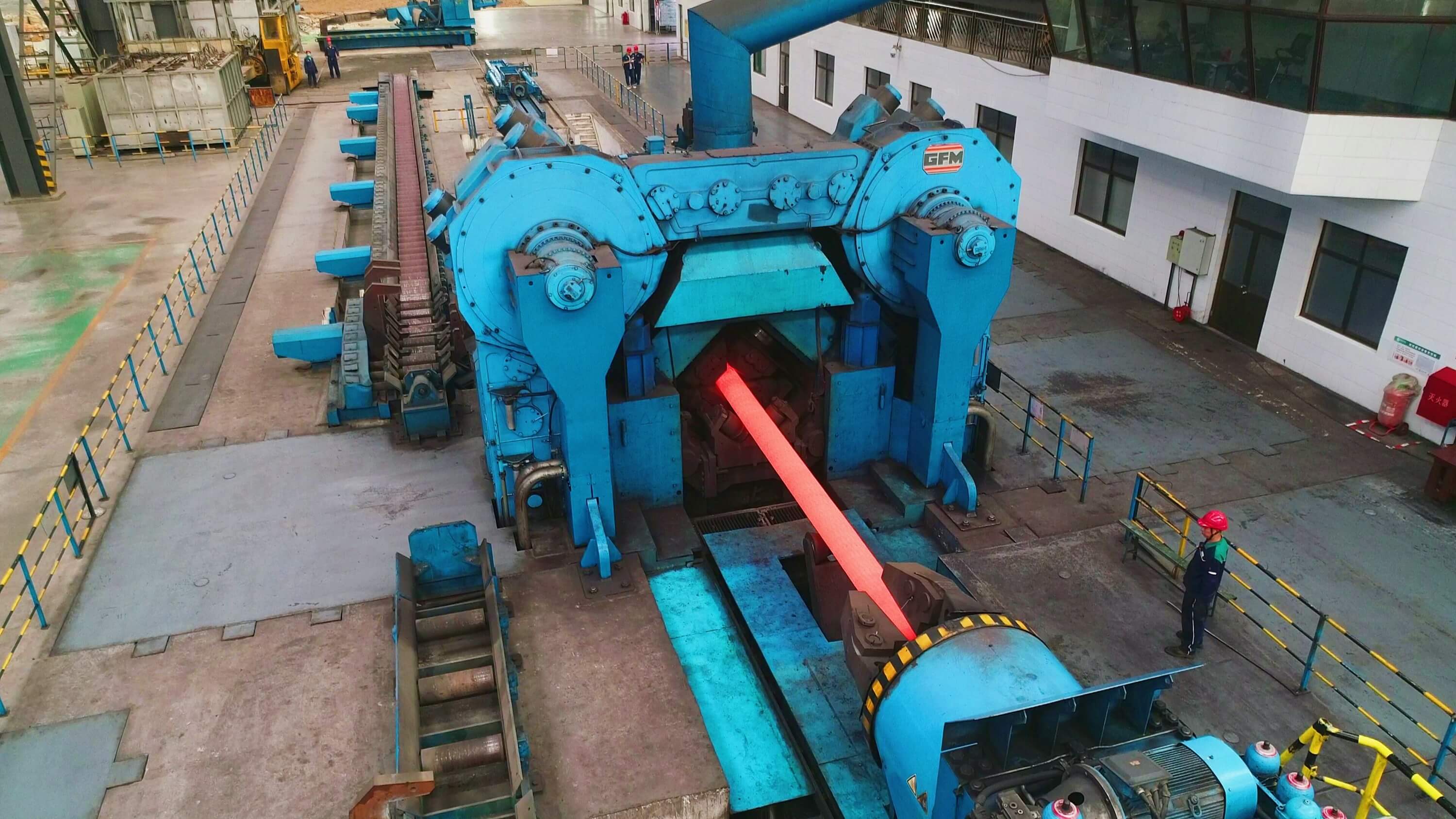

锻造—全球最大的奥地利GFM RF100型2000吨径向精锻机

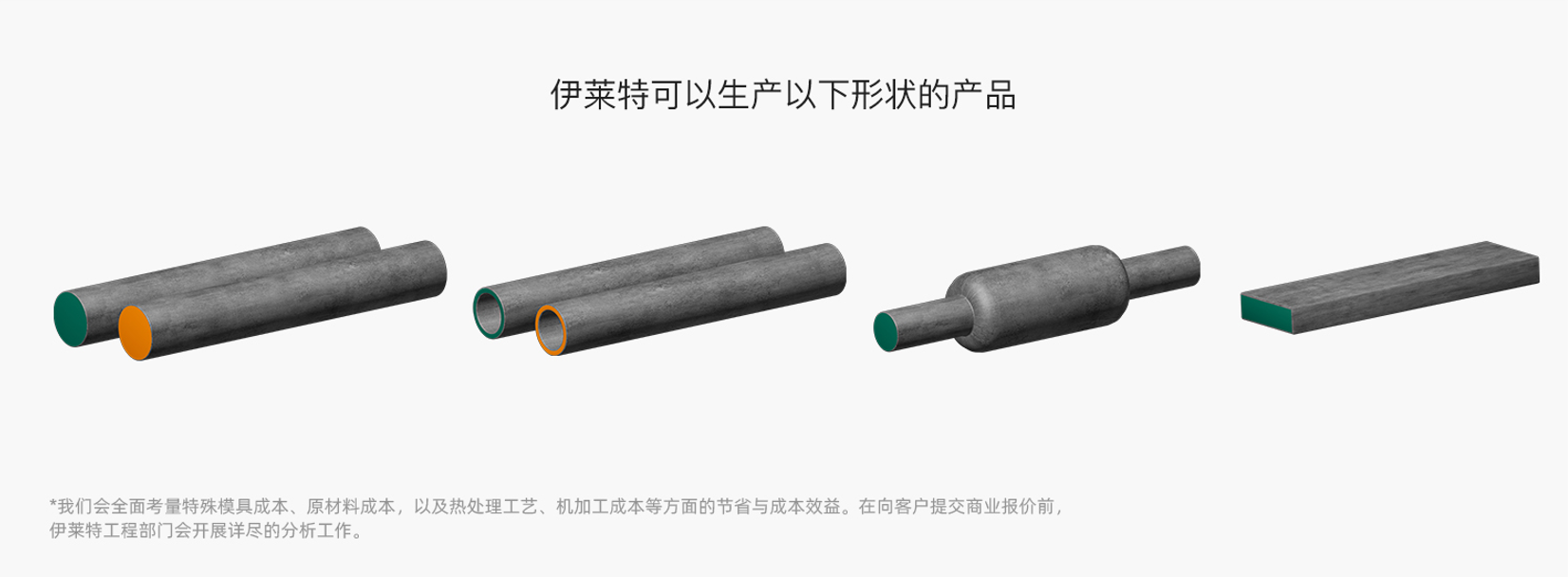

伊莱特(济宁)公司拥有全球最大的奥地利GFM RF100型2000吨径向精锻机、3T/8T/12T电液锤、2M/5M辗环机、1600T/2000T/4500T快锻机,可以采用热锻、冷锻或温锻生产,适用于各种不锈钢和特种材料,包括钛合金、高温合金和无磁钢的锻造,生产圆、方、扁、矩型截面、阶梯轴以及厚壁管等超长产品。

展开更多 +

收起 -

热处理—高标准满足客户热处理需求

伊莱特(济宁)公司配套有20余台热处理炉,包括天然气台车式退火炉、电阻式热处理炉以及淬火线等,最大长度20M。

展开更多 +

收起 -

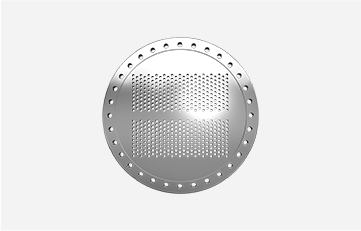

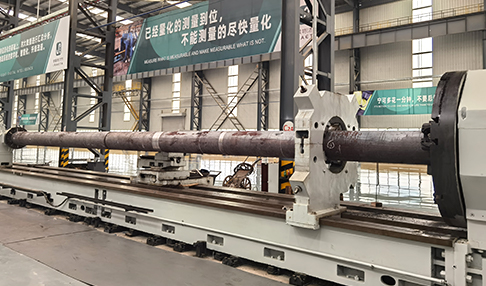

机加工—先进的机加工能力

伊莱特(济宁)公司机加工车间生产现场5万平方米,拥有数控立车20余台、数控卧车20余台、大型数控卧式车床10余台,龙门铣床3台、深孔镗床2台、大型立锯2台、卧式锯床7台、无心车床、无心磨床各1台,扒皮机3台。其中数控立车加工最大直径中4000MM;锯切规格中100-1500MM;大型卧式车床最大加工直径中1200MM,最大长度18M;深孔钻镗床加工规格600-1300MM;铁床加工3M*10M。

展开更多 +

收起 -