全球清洁能源产业链的重要一环

伊莱特的大部分产品被用于核电、水电、风电、光热等清洁能源领域。作为全球清洁能源产业链上的一环,我们也极为重视自身生产环节的减碳制造,除了使用短流程钢作为主要原材料,我们在生产过程还使用了大量减碳制造技术,如原材料热送、富氧燃烧、金属构筑、近净成形等。

丰富的减碳技术经验

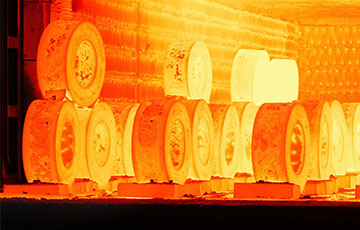

金属构筑,增材制造

某些合金在超过100吨后,钢锭利用率只有70%左右。不同于钢水浇筑的钢锭,金属构筑成形技术,使用小尺寸高质量钢坯,通过真空封装、高温焊合等工艺,以小制大,利用率高达95%以上。在提高质量的同时,有效降低了炼钢产生的碳排放,和无效材料加热浪费的能源。

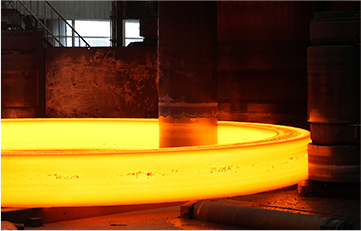

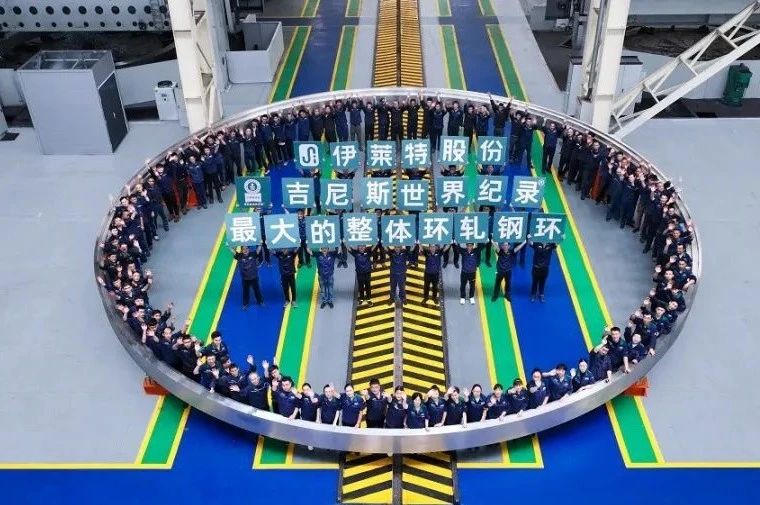

整体轧制,近净成形

超级锻件要使用的钢材从几十吨到几百吨不等。近净成形技术通过特殊设计,模仿锻件成品尺寸,减少加工余量,进而降低原材料以及加热产生碳排放。一些产品的原材料消耗甚至能降低30%,您的采购成本也能大幅降低!

什么是绿色钢铁?

完善的废弃物管理

保护大气

我们严格遵循法律法规,使用SCR脱硝设备、脉冲布袋除尘设备、CEMS在线监测系统,持续管控公司的废气处理,确保排放合规。

固体废弃物管理

针对生产过程中产生的废钢、余料等,我们构建了系统化的回收流程,重新转化为高价值原材料,以实现环境保护和资源节约的双重目标。

通过新能源的使用来实现减碳目标

富氧燃烧

自然空气中,氧气占比约为21%。富氧燃烧技术通过增加氧气比例,提高加热炉的燃烧效率,同时降低氮氧化物排放。

屋顶光伏

我们在主要建筑上总计安装了26 MW的屋顶光伏,年发电量超过2000万度,能够覆盖全部的办公、空调用电,以及部分生产用电。