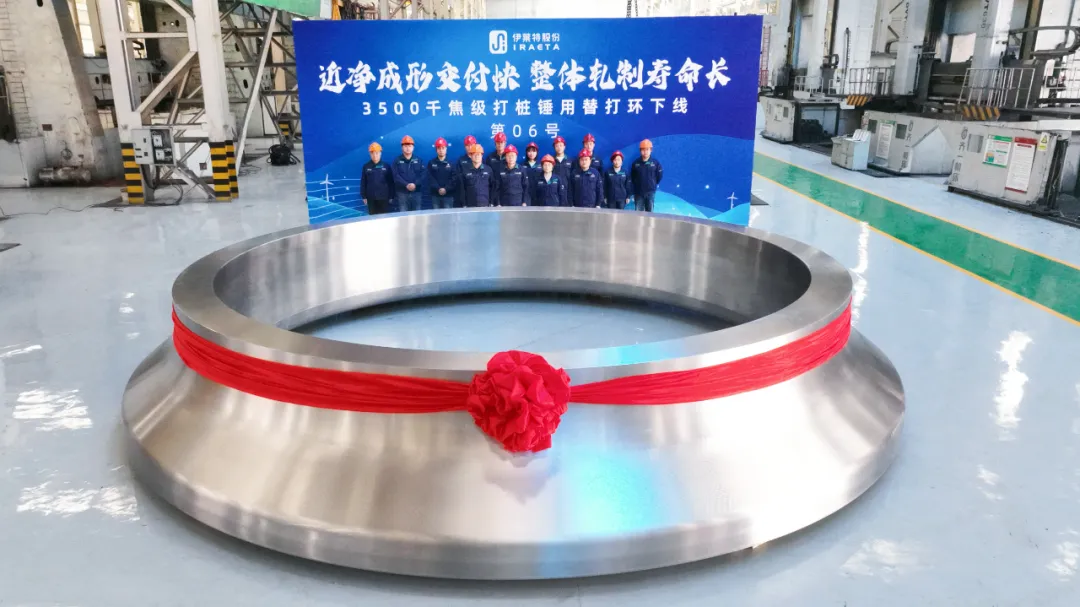

近净成形交付快,整体轧制寿命长——伊莱特第06号3500千焦级打桩锤用替打环成功下线

2022-10-26

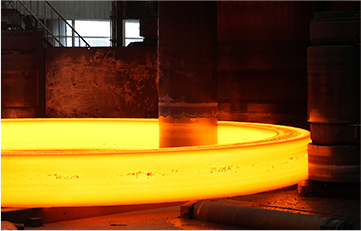

2022年10月25日,一件直径7.6米的超大型替打环锻件从伊莱特成功发运。这是伊莱特继2020年为国内首台自主研发的3500千焦液压打桩锤提供替打环后,成功制造的第6件百吨级重型替打环。

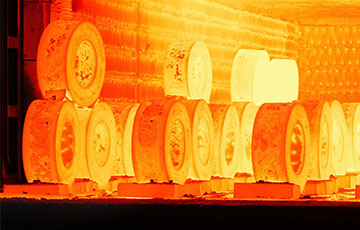

第06号3500千焦级打桩锤用替打环下线

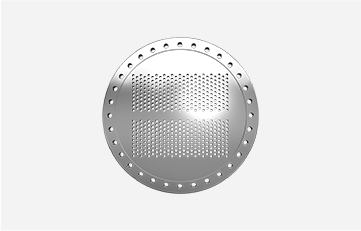

大型海洋液压打桩锤是海上风电、油气平台等海洋工程施工的关键设备。由于打桩锤的锤芯和钢桩的直径尺寸存在较大差异,安装钢桩时便需要给它带一个“帽子”——替打环。替打环头小底大,上部承受锤芯的击打,下部将冲击能量传递给钢桩,最终将重达上千吨的钢桩牢牢地“钉”在海床上,为后续的海上作业提供安全稳定的基础。

作为海上液压打桩锤的重要部件之一,重型替打环制造难度大,交付周期长,国内鲜有厂家具备生产能力。2020年,伊莱特与北京机电研究所合作,首次采用整体轧制、近净成形工艺,成功制造出直径7.6米的3500千焦级打桩锤用替打环,刷新当时国内同类部件的尺寸及重量纪录。

国内首台自主研发的3500千焦液压打桩锤用替打环

相较于传统的自由锻方式,利用整体轧制,近净成形工艺制造的超大环形变截面锻件,在锻件余量、材料性能均匀性、生产效率以及材料利用率上都有着非常明显的优势。该方式不仅能缩短生产周期,实现产品的及时交付,增加锻件在服役条件下的使用寿命,还能降低业主或客户的采购成本,实现一举多得。

目前,在大型锻件近净成形领域,伊莱特占有重要市场地位,拥有先进的制造装备和丰富的量产经验,环件最大可加工直径达到16米,高度最大可达3米。