不止核电,轴承工程师们也开始使用这种设计!

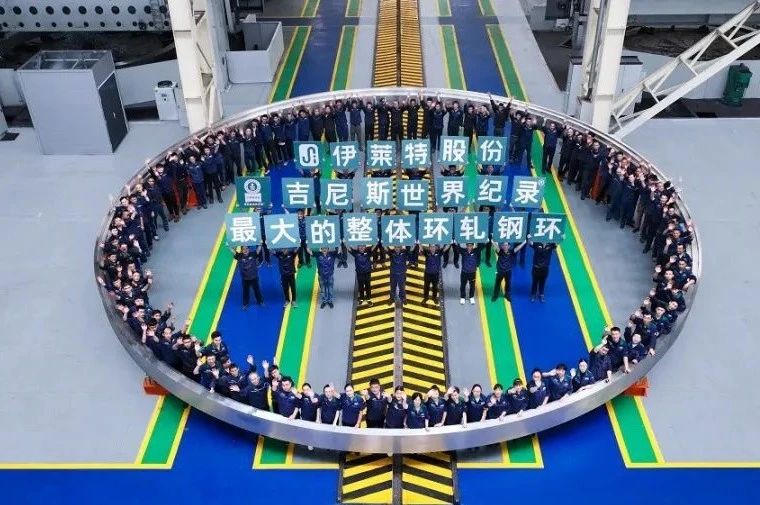

近日,最后一批风电安装船起重机用轴承环从伊莱特顺利发运。该订单共包括9件直径在12米-14米的超大轴承环,其中最大的一件轴承环直径超过13.8米,这意味着无缝整体式轴承的纪录将很快由中国企业创造。

轴承的基本结构主要有内圈、外圈、滚动体、保持架等组成,其中轴承的内外圈又分为整体式和分段式。对于超大直径轴承,由于很长一段时间全球最大轧环机的加工能力仅在十米左右,因此超大直径轴承一般超过9米就要使用分段式设计,即一个轴承圈由多个弧形锻件组装而成。

但这种设计会带来两大问题:

首先是加工难度大,加工周期长,要把多块矩形锻钢加工成统一的弧度,且在性能上保持一致,难度非常大。且一旦其中一块的性能过高或过低,都会导致轴承在服役过程中部分区域过度磨损。

其次是海上工作环境恶劣,风大浪高,盐雾腐蚀高,起重设备在高载荷连续作业下,整体式轴承会比分段式轴承拥有更高的精确度和更长的使用寿命,也会极大降低因为维修保养带来的停机时间,缩短设备的投资回报周期。

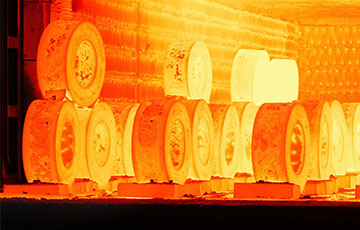

图片来源于网络

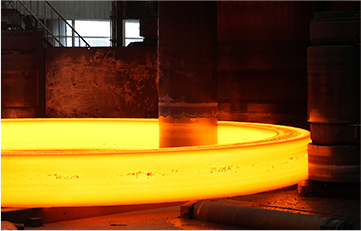

2021年10月份,伊莱特首次采用整体轧制工艺,为洛轴提供了一套直径11.5米的整体式锻环,开启了超大型整体轴承制造的国产化时代。

2021年伊莱特为洛轴提供的直径11.5米的整体式锻环

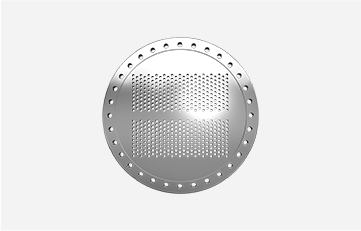

此后,伊莱特与洛轴一直保持着良好的战略合作关系。今年伊莱特与洛轴再度联手,制造了9件超大直径整体式轴承环。据悉,这批产品将组成3套轴承,后续将被安装在三艘千吨级重型海上风电安装船绕桩式起重机上,为各个风场的海上风电安装提供装备支持。

这批产品的成功下线,在工程领域具有重要的引领作用,为“大国重器”的工程师们设计研发高端海洋工程装备提供更具想象力的设计空间。下一步,伊莱特将持续进行科技创新,为推动海上风电产业的高质量发展,实现“碳达峰、碳中和”目标,推动我国绿色发展迈上新台阶贡献力量。