Introduction

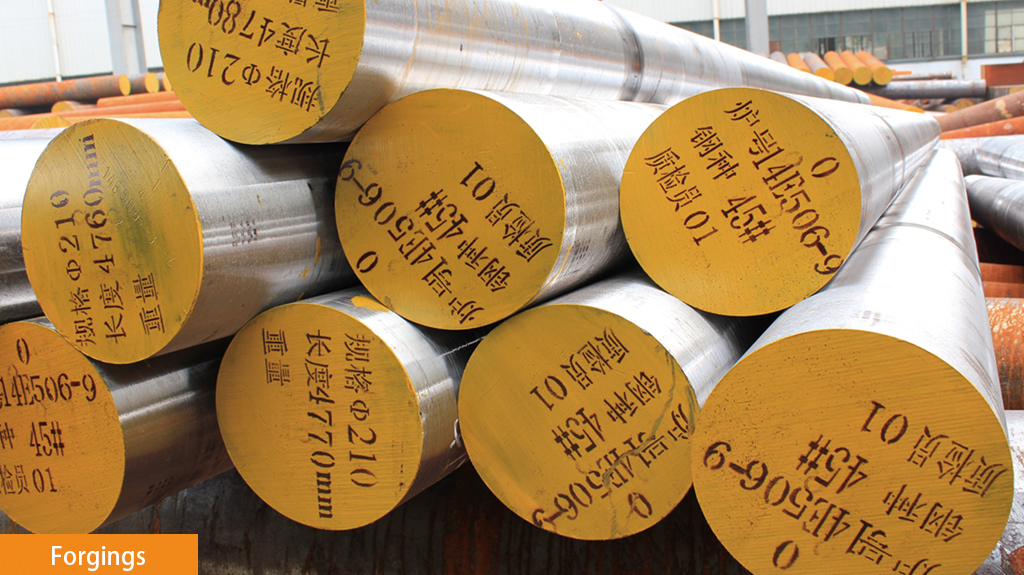

As a wholly-owned subsidiary of Iraeta Energy Equipment Co., Ltd., Iraeta (Jining) High-tech Equipment Co., Ltd. is a manufacturing concern that specializea mainly in a diversified range of products within the forgings industry.Professional development, production and sales of special steel. It mainly produces high-strength industrial materials, including 13 main categories of high-quality special steel casting ingot, forgings and forged pieces of more than 300 types which include alloy steel, steel for military use, die steel, pinion steel, bearing steel, roll steel and stainless steel. The maximum diameter of forgings can reach 1,200mm and the maximum length 25m.

Its products have been widely used domestically in large-scale locomotives, machinery, tooling, automobile, shipbuilding, petrochemical, aerospace, nuclear power, wind power, military industry and other industries, while large quantities also being exported to Australia, Germany, Italy, France, the United States, Japan, South Korea, Turkey, Brazil and other European, American and Asian countries and regions. The Company has cooperation experiences in Chinese national key projects, such as national aerospace launchers, Olympic torch lifter, the Three Gorges large-sized starting gate, large aircraft mould manufacturing, high-speed EMU and large and heavy coal shearer.

Iraeta Group is highly capable in technology and product R&D. Cooperating with Institute of Metal Research of Chinese Academy of Sciences, it established the Li Yiyi Academician Workstation and carried out in-depth cooperation in R&D, manufacturing and achievement transformation of high-end metal materials and forgings. And the Company has maintained long-term good cooperation with experts from well-known scientific research institutes and universities, such as Central Iron & Steel Research Institute, China Institute of Atomic Energy, School of Materials Science & Engineering of Shandong University, HRG Institute (Shandong) of Intelligent Equipment, School of Materials Science & Engineering of Shandong Jianzhu University and Kunming University of Science and Technology.

The Company has currently formed a complete production and processing system integrating high-speed forging, precision forging, heat treatment, fine machining and physical and chemical inspection. It has introduced the world's first Austrian GFM RF100 2000t radial precision forging machine and together with its parent company, Iraeta Corporation’s world first φ16m super ring rolling mill from German SMS Group. The company now boasts a world-leading production capacity in forgings, forged pieces, ring rolling, cylinder rolling and other fields.

Products:

Forging products: Round bar steel, block, roll, forgings, hollow stepped shaft .

Note: The DIN, EN, ASTM, JIS and other standard products can be customized according to requirements.

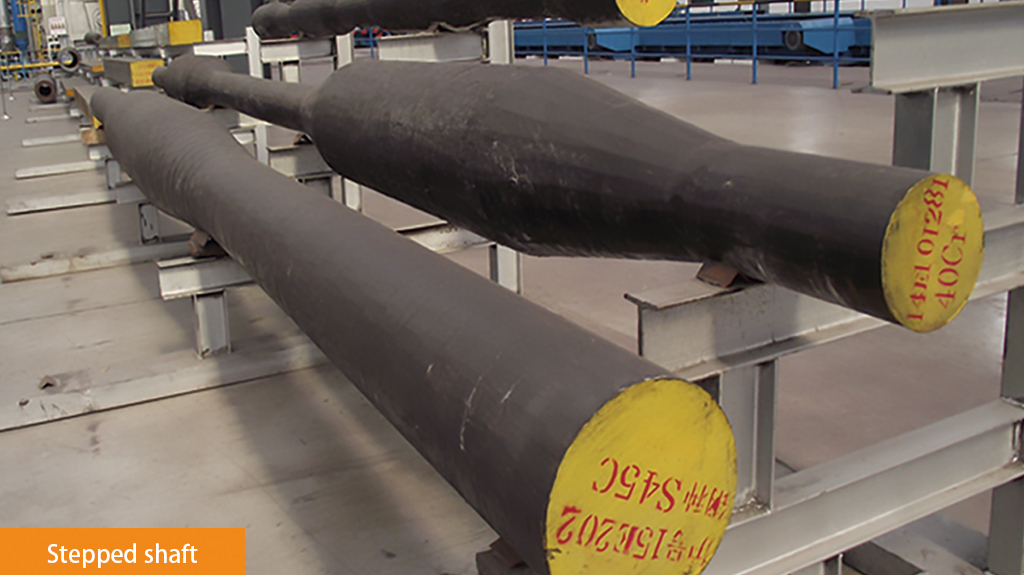

Precision forging products: Die bar, plate, forged pipe, non-magnetic drill collar, titanium alloy pipe, stepped shaft, high-temperature alloy, pipe die.

Note:

the tube length is 12 meters, the maximum outer diameter is 500-720mm, the tolerance is ±3.5-5.5mm

Pipe length 12 meters, inner diameter 160-500mm, tolerance ±2.5-4.5mm

MAIN EQUIPMENT:

Forging system:The Company has 3 sets of 5t electro-hydraulic hammers, 1 set of 800t, 1,600t, 2,000t and 4,500t rapid forging presses, and has introduced the world's first Austrian GFM RF100 2000t radial precision forging machine, with fast forging speed and high precision.

The world's most advanced GFM RF100 2000t radial precision forging machine introduced by the Company is suitable for forging carbon structural steel, tool steel, various stainless steel and special materials (titanium alloy and high temperature alloy). It can be used for producing round, square, flat, rectangular cross section, stepped shaft and forged thick-wall pipe, as well as producing special type products (non-magnetic drill collar, etc.) with special forging process (hot forging, cold forging or warm forging).

Heat treatment system: It is equipped with nearly 50 heat treatment furnaces, trolley heating furnaces, chamber natural gas heating furnaces, resistance heating furnaces, etc.

Machining system:The company has over 20 sets of large and medium-sized sawing equipment, with sawing specifications of φ100-1,500mm. The specifications of the round billet grinding machine are φ80-800mm; the maximum processing diameter of the large-sized horizontal lathe is φ1,200mm; the processing specification of the deep-hole drilling and boring machine is 600-1,300mm,Machining specification of coreless lathe φ 100mm-300mm.

Parameter

Carbon tool and die steel

Alloy tool and die steel

Carbon structural steel

Alloy structural steel

Gearing steel

Bearing steel

Spring steel

Stainless steel

Heat-resistant steel

High-speed steel

High-temperature alloy

Titanium alloy

Non-magnetic drill collar

Round steel

Square steel

Flat steel

Hot forged pipe fittings and non-magnetic drill collars