Introduction to Block Forgings

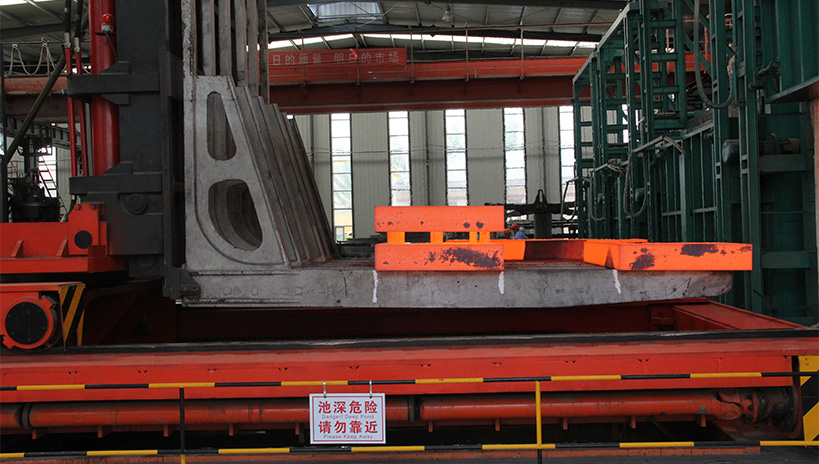

IRAETA has various types of forging equipment covering specifications such as 3/8/3000/3150/4000/10000/13500 tons, and can provide customers with forged steel molds and blocks of various sizes. Whether it is steel mold or block forgings for final equipment, we can provide one-stop service from raw material customization, forging, heat treatment, to five-axis precision machining.

Metal Construction Technology - Achievement of China's Top ScientificResearch Team

Developed by the team led by academician Li Yiyi, from the Institute of Metal Research, Chinese Academy of Sciences, metal construction technology is now used for diverse production requirements at IRAETA. The Institute of Metal Research, Chinese Academy of Sciences is a leading metal material R&D organization in China, and the team led by academician Li Yiyi has made significant achievements in research and manufacture of materials for key components in major projects, such as turbine runners for the Three Gorges Project, high-speed railway coaches, nuclear power pressure vessels and large marine crankshafts.

Metal construction technology uses the principles of architecture in seal welding homogeneous plates in a vacuum environment; a heat forging process is used to seamlessly form plates, and this technology has the following advantages:

Homogeneous and Denser Materials

Use of smaller metal billets as building blocks can achieve almost simultaneous solidification, ensuring improved metal composition uniformity compared to traditionally-casted large-scale ingots. Large metal components manufactured in this way are less likely to have serious macrosegregation, and concentrated shrinkage cavities and porosities are less likely to be found. After deformation, insulation, and multi-forging, the density of the welding interface is higher than that of forgings made using traditional casting of whole blanks.

Purer Materials

Use of smaller metal billets as building blocks ensures lower costs and efficient processing, due to which numerous refining methods can be flexibly used to purify elements. Thus, large metal components manufactured in this way have higher purity compared to forgings made using traditional casting of whole blanks.

Parameter

Material

Size Range

Piece Weight Range

Heat Treatment

Testing

Processing