Introduction to Ring Forgings

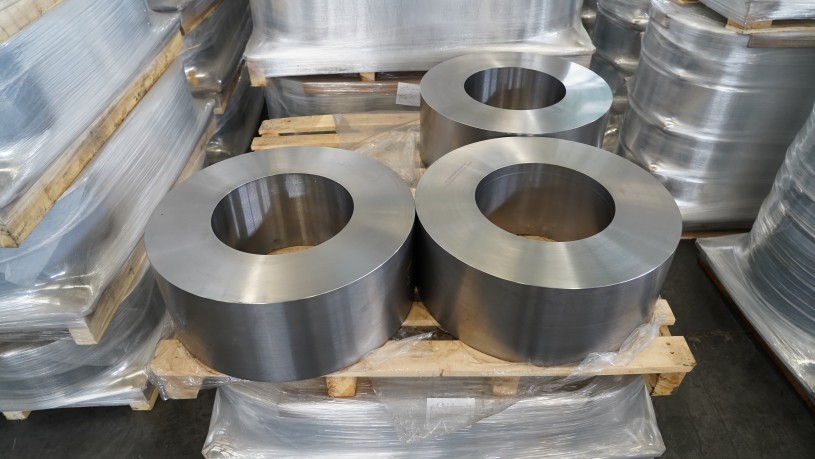

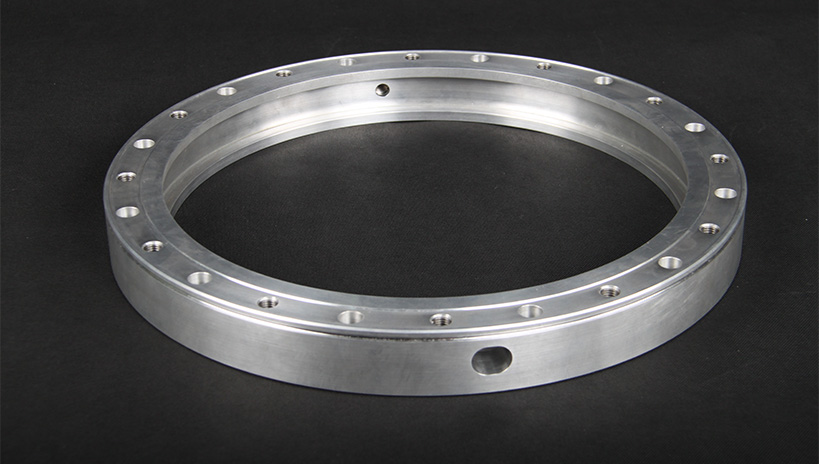

IRAETA occupies a very important position and has rich manufacturing experience and success in the ring forgings market in China. IRAETA is the chair unit of the ring forging committee for the Confederation of Chinese Metal Forming Industry. IRAETA has 9 vertical & horizontal ring rolling production lines with various machining modes. We can provide all kinds of small and medium ring forgings such as bearing collars and aluminum magnesium alloy ring forgings used in GIS gas insulated switchgear system, and large-scale forgings and extra-large ring forgings for wind turbines, large-scale semi-autogenous mill, harbor machinery and TBM (tunnel boring machine). We also introduced the world’s first super-grade rolling mill from Germany’s SMS Meer, which can manufacture rings with a diameter up to 16 m and height up to 3 m.

Creating More Possibilities – RevolutionarySuper-Rolling Mill makes 16 m Diameter Rings

Large-diameter bearings, slewing bearings and gears are widely used in large equipment including harbor machinery, TBM, barge cranes and large-scale semi-autogenous mills, as well as in fields of hydropower, nuclear power, marine engineering, etc. Compared with casting, the forging process can effectively eliminate pores, shrinkage cavities, slag inclusions and other defects, in other words, forgings possess better quality and mechanical performance. The SMS MEER super-rolling mill imported by IRAETA is another marvel in the history of machinery manufacturing. With this super machine capable of manufacturing rings with a diameter up to 16 m and height up to 3 m, engineers and technicians have an opportunity to make their bold concepts and ideas into reality.

Parameter

Material

Size Range

Piece Weight Range

Heat Treatment

Testing

Processing

Guestbook

Relevant

- ISO 9001:2015.pdf

- ISO 14001:2015.pdf

- ISO 45001:2018.pdf

- ISO 50001:2018.pdf

- CE(EN1090).pdf

- CNAS LABORATORY CERTIFICATE.pd

- CPR.pdf

- PED.pdf

- TUV LABORATORY CERTIFICATE.pdf

- ABS CERTIFICATE.pdf

- BV CERTIFICATE.pdf

- CCS CERTIFICATE.pdf

- DNV CERTIFICATE.pdf

- KR CERTIFICATE.PDF

- LR CERTIFICATE.pdf

- NK CERTIFICATE.pdf

- RINA CERTIFICATE.pdf